SND Valdiklio komplektas ROMANO AIS 2 4 cil.

Su PVM:

€272.87

ANTONIO INJECTION SISTEMA yra "Romano Srl" sukurta naujausios kartos sekvensinė 4 cilindrų versijos sistema. ANTONIO Elektroninis valdiklis yra patentuotas, dėl naujų funkcijų ir pažangiausių technol..

- Gamintojas:

Romano

Romano - Prekės kodas: 2950

- Gamintojo kodas:

- Prekės prieinamumas sandėlyje:

Žymos: Romano

ANTONIO INJECTION SISTEMA yra "Romano Srl" sukurta naujausios kartos sekvensinė 4 cilindrų versijos sistema.

ANTONIO Elektroninis valdiklis yra patentuotas, dėl naujų funkcijų ir pažangiausių technologijų yra neprilygstamas rinkoje, jo pagrindinės charakteristikos:

- Galimybė įdiegti tiek SND, tiek SGD, visų tipų variklius nuo 2 iki 4 cilindrų NETIESIOGINIO ĮPURŠKIMO (nuoseklios, pusiau nuoseklios ir visos grupės). Ta pati komunikacijos programinė įranga leidžia lengvai valdyti skirtingus variklių tipus.

- Galimybė emulioti benzino slėgio sensorius, kai kurių transporto priemonių su netiesioginiu įpurškimu (indirect), tokių kaip OPEL, Jaguar, Ford, be išorinių emulatorių.

- Automatinė OBD parametrų konfigūracija tiesioginio įpurškimo transporto priemonėms

- Lengvas purkštukų pajungimas (atkirtimas)

- Nauja aparatinė įranga turi novatoriškas funkcijas ir labai naujus kompiuterio algoritmus ir koncepcijas, skirtas oro / dujų srauto mišiniui valdyti visomis variklio darbo sąlygomis.

Programinės įrangos sąsaja sukurta rūpestingai ir yra lengvai naudojama:

- Ji yra vartotoju patogi ir lengvai pritaikoma;

- Leidžia greitai susijungti su elektroniniu valdikliu;

- Atlieka visų sistemos komponentų diagnozę, tikrinant galimas problemų priežastis;

- Turi skyrių "Žinynai", kuriuose montuotojas ir galutinis vartotojas gali rasti visą naudingą informaciją, reikalingą tinkamai naudoti sistemą

- Pagrindinė laidų pynė: Labai lengva sumontuoti ir sujungti su visomis jungtimis dėl esamų jungčių (laidai be jungčių yra papildomi).

|

Palyginimo lentelė |

ANTONIO 4 cil. (2-3-4 cilindrai) |

ANTONIO 2 - 4 cil. (2-3-4 cilindrai) |

ANTONIOS 8 cil (5-6-8 cilindrai) |

ANTONIO e (2-3-4cilndrai) |

|||

|

ELEKTRONINIS VALDIKLIS su "daugialype" aparatine įranga Nauja įranga leidžia sumontuoti dujų įrangą (SND ir SGD) į automobilius su tiesioginiu (direct injection) netiesioginiu (indirect injectio), bei dyzelinius variklius turinčius automobilius, naudojant vieną ir tą patį elektroninį valdiklį. |

+ |

+ NO DIRECT INJECTION |

+ |

+ NO DIRECT INJECTION |

|||

|

KURO TIPAS SND/SGD |

+ | + | + | + | |||

|

Palaikomas cilindrų kiekis |

Min 2 - Maks 4 cilindrų |

Min 2 - Maks 4 cilindrų |

Min 2 - Maks 8 cilindrų |

Min 2 - Maks 4 cilindrų |

|||

|

SAVIKALIBRACIJA Automatinis MAP lentos ir reduktoriaus darbinio slėgio nustatymas |

+ |

+ |

+ |

+ |

|||

|

BENZININIŲ PURKŠTUKŲ EMULIATORIUS Atkirtimui benzino purkštukams nereikės ieškoti minusinio laido. nesvarbu (tinkamai ar atvirkščiai) sistema atpažins ir neiškils jokių problemų. |

+ |

+ |

+ |

- |

|||

|

BENZINO SLĖGIO EMULIATORIUS “AUTOMOBILIAMS SU NETIESIOGINIU ĮPURŠKIMU" Įrenginys integruotas į elektroninį valdiklį. Nereikia montuoti jokių papildomų emuliatorių. |

+ |

+ |

+ |

- |

|||

|

BENZINO SLĖGIO EMULIATORIUS AUTOMOBILIAMS SU TIESIOGINIU ĮPURŠKIMU AUTOMATINĖ kalibravimo ir emuliacijos parametrų nustatymo procedūra |

+ |

- |

+ |

- |

|||

|

SND/SGD REDUKTORIAUS SLĖGIS NEW Automatinis programuojamo darbinio slėgio reduktoriaus reguliavimas (SND / SGD) |

+ |

+ |

+ |

+ |

|||

|

RPM SIGNALO NUSKAITYMAS Kad ir nereikia reikia jungti šio laido, tačiau laidų pynėje vis tiek yra RUDAS laidas, skirtas konkretiems automobiliams konkrečioms funkcijoms. |

+ |

+ |

+ |

+ |

|||

|

RPM SIGNALO INTENSYVUMAS NEW Kai kuriuose konkrečiose situacijos, kur RPM signalas yra labai žemos įtampos, prijungus RUDĄ laidą, jums nereikės įdiegti jokio išorinio signalo stiprintuvo ir daugiklio. |

+ |

+ |

+ |

+ |

|||

|

DUJOS / BENZINAS VALDYMAS Benzino tiekimo valdymo algoritmai laisvoje eigoje ir dideliais sūkiais. Patogi valdymo programinė įranga, novatoriškas ir intuityvus dizainas. |

+ |

+ |

+ |

+ |

|||

|

DIAGNOSTIKA Inovatyvios diagnostikos funkcijos su klaidų kodų sąrašu, klaidos kilmės rodymas ir problemų sprendimas, kad būtų išspręstos problemos tik po siūlomų procedūrų. |

+ |

+ |

+ |

RIBOTOS DIAGNOSTIKOS FUNKCIJOS |

|||

|

ĮPURŠKIMO SEKA Pažangiosios įpurškimo sekos valdymo algoritmas (fazinis ratas). |

+ |

+ |

- |

+ |

|||

|

FUNKCIJ Rec. Galimybė fiksuoti veikimo parametrus bet kuriuo metu |

+ |

+ |

+ |

+ |

|||

|

TEMPERATŪROS VALDYMAS Reduktoriaus temperatūra - DUJŲ temperatūra (jutikliai 4K7 ir 2K2) Automatinis dujų mišinio kompensavimas pagal temperatūros vertes |

+ |

+ |

+ |

+ |

|||

|

DUJŲ SLĖGIO VALDYMAS Automatinis perėjimas į benziną, kai dujų slėgis yra mažas. Automatinis dujų mišinio kompensavimas, pagrįstas slėgio reikšmėmis darbo sąlygomis. |

+ |

+ |

+ |

+ |

|||

|

VARIKLIŲ VALDYMAS Turbo, Valvetronic - Multi-air, "Start" ir "Stop", netiesioginis ir tiesioginis įpurškimas |

+ |

NO DIRECT INJECTION |

+ |

NO DIRECT INJECTION |

|||

|

OBD VALDYMAS ATOMOBILIAMS SU NETIESIOGINIU VALDYMU Prisijungimas gali būti atliekamas automatiškai arba pasirenkant vieną iš šių standartų: ISO 9141-2 KWP2000 FAST - KWP2000 SLOW CAN STANDARD 250 - CAN EXTENDED 250 CAN STANDARD 500 - CAN EXTENDED 500 |

+ |

+ |

+ |

- |

|||

|

OBD VALDYMAS AUTOMOBILIAMS SU TIESIOGINIU ĮPURŠKIMU AUTOMATINĖ procedūra ryšio tipui ir "TARGET" užfiksuoti |

+ |

- |

+ |

- |

|||

|

RESET DTCNEW Su laidais ir prijungtu OBD galite:

|

+ |

+ |

+ |

- |

|||

|

ADAPTATIVITY Automatinis map lentos pritaikymas pagal OBD nustatytus parametrus. |

+ |

+ |

+ |

- |

|||

|

TRUMPŲ ĮPURŠKIMŲ VALDYMAS – automobiliams su netiesioginiu ir tiesioginiu įpurškimu Trumpų įpurškimų (papildomų įpurškimų valdymas tinkama slinktimi |

+ |

+ |

+ |

+ |

|||

|

DVIGUBO ĮPURŠKIMO VALDYMAS - automobiliams su tiesioginiu įpurškimu Speciali kontrolė (papildomos įpurškimo) per atitinkamą map lentą |

+ |

- |

+ |

- |

|||

|

INSTALIACIJOS TESTAS Automatinis benzino purkštukų pajungimo valdymas ir rankinis dujų purkštukų atitiktis |

+ |

+ |

+ |

+ |

|||

|

KALBŲ VALDYMAS Programa yra daugiakalbė

|

+ |

+ |

+ |

+ |

|||

|

AUTOMOBILIŲ PAJUNGIMO SCHEMOS Visas automobilių montavimo schemas rasite programinėje įrangoje |

+ |

+ |

+ |

+ |

|||

|

INSTRUKCIJOS Programinės įrangos viduje rasite toliau nurodytus failus ir galite juos rasti atskirai: ANTONIO ECU Error codes; Installer Manual; AIS Software Manual; End-User Manual ( printable)

|

+ |

+ |

+ |

+ |

|||

|

JUNGIKLIS Naujos konstrukcijos paskutinės kartos transporto priemonių prietaisų skydelyje |

+ |

+ |

+ |

+ |

|||

|

ELEKRONINIO VALDIKLIO DĖŽUTĖ atsparumo lygis IP67 |

PLASTIKINIS - ALIUMINIS |

PLASTIKINIS - ALIUMINIS |

ALIUMINIS |

PLASTIKINIS |

|||

|

LAIDŲ PAJUNGIMAS |

|

|

|

|

|||

|

Visi pagrindiniai elektroninio valdiklio laidai yra su jungtimis, visi laisvieji laidai yra papildomi |

+ |

+ |

+ |

+ |

|||

|

Maitinimo rėlė yra valdymo bloko išorėje, jai skirtoje dėžutėje.. |

+ |

+ |

- |

+ |

|||

|

DUJŲ elektromagnetiniu vožtuvus valdo elektroninis valdiklis, valdantis neigiamą polių (įžeminimą), tai yra labai svarbu: nesupjaukite jungčių ir nenaudokite kitų įtaisų į šiuos išėjimus - teigiamus arba įžeminimą. |

+ |

+ |

- |

- |

|||

|

Visi prietaisai, tokie kaip apsukų variatorius arba kiti emuliatoriai, kuriuos reikia valdyti DUJŲ elektroniniu valdikliu, turėtų būti prijungti prie GELTONO-RAUDONO laido. Ši išvestis yra aktyvi (+ 12 V srovė) tik tada, kai transporto priemonė perjungiama į dujas, kad būtų išvengta veikimo sutrikimų važiuojant benzinu arba perjungiant.

|

+ |

+ |

+ |

- |

|||

|

PROGRAMOS ATIDARYMAS Programinė įranga yra visiškai pritaikoma

|

+ |

+ |

+ |

+ |

|||

|

ĮĖJIMO ĮTAMPA |

Baterijos įtampa ( 8 ÷ 16V ) |

||||||

|

DARBINĖ TEMPERATŪRA |

- 40°C ÷ 125 °C |

||||||

|

SROVĖS NAUDOJIMAS |

Laisvais sūkiais Iq = 50 mA Miego rėžime Iqs< 1µA |

Laisvais sūkiais Iq = 50 mA Miego rėžime Iqs< 1µA |

Laisvais sūkiais Iq = 70 mA Miego rėžime Iqs< 1µA |

Laisvais sūkiais Iq = 37 mA Miego rėžime Iqs< 50µA |

|||

|

DUJŲ PURKŠTUKŲ IŠĖJIMAS |

Nuo 2 ÷ 4 PURKŠTUKŲ Imax 6 Nepertraukiamas kiekvienam ortakiui su maksimalia 16V baterija |

Nuo 2 ÷ 4 PURKŠTUKŲ IImax 6 Nepertraukiamas kiekvienam ortakiui su maksimalia 16V baterija |

Nuo 2 ÷ 8 PURKŠTUKŲ Imax 6 Nepertraukiamas kiekvienam ortakiui su maksimalia 16V baterija |

Nuo 2 ÷ 4 PURKŠTUKŲ Imax 6 Nepertraukiamas kiekvienam ortakiui su maksimalia 16V baterija |

|||

|

ELEKTROVOŽTUVŲ IŠĖJIMAI |

Pmaks Tot. 130W; Imaks 9,6 A Reduktoriaus išėjimas + balionų išėjimas |

||||||

|

TINKANTYS KURO LYGIO SENSORIAI ROMANO standartinis SGD ir SND pasirinktinai 0 ÷ 90 Ohm Linijiniai aktyvūs sensoriai 0 ÷ 5V for Pajungimą žiūrėkite instrukcijoje |

+ |

+ |

+ |

+ |

|||

|

ROMANO MAP SENSORIUS Plastikinė dėžutė su IP67 lygio apsauga |

+ |

+ |

+ |

- |

|||

|

ROMANOMAP Sensorius (Skaitmeninė signalų sąsaja) Plastikinė dėžutė su apsaugos lygiu IP67

|

- |

- |

- |

+ |

|||

|

REDUKTORIAUS TEMPERATŪROS SENSORIUS Standartinis ROMANO 4.7 KΩ - 2.2 KΩ

|

+ |

+ |

+ |

+ |

|||

|

DUJŲ TEMPERATŪROS SENSORIUS Standartinis ROMANO 4.7 KΩ - 2.2 KΩ

|

+ |

+ |

+ |

+ |

|||

|

LAMBDA SENSORIUS 0 ÷ 1 V Nuskaitymo ir emuliacijos |

+ |

+ |

+ |

TIK NUSKAITYMO |

|||

|

LAMBDA SENSORIUS 0 ÷ 5 V Nuskaitymo ir emuliacijos |

+ |

+ |

+ |

TIK NUSKAITYMO |

|||

|

LAMBDA SENSORIUS UEGO Emulacija |

+ |

+ |

SU IŠORINIU EMULIATORIU |

- |

|||

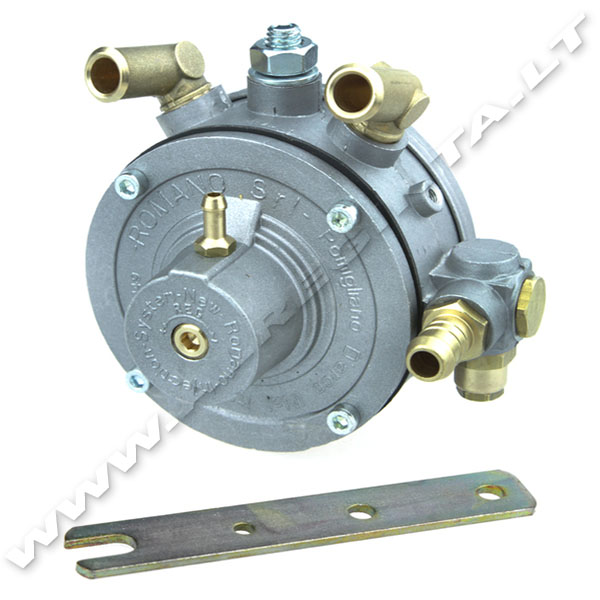

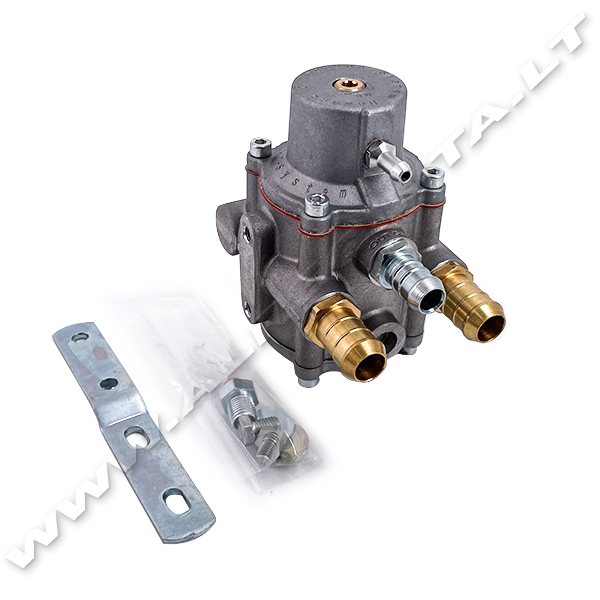

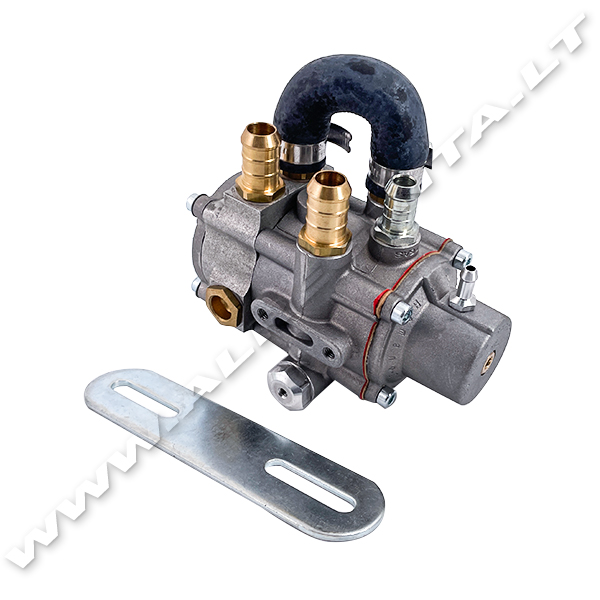

Prekės atspalvis gali skirtis nuo matomo nuotraukoje. Prekės aprašymas yra bendro pobūdžio, jame nebūtinai yra paminėtos visos prekės savybės. Internetinėje parduotuvėje skelbiamos prekių kainos, akcijos gali skirtis nuo prekių kainų, akcijų taikomų fizinėje parduotuvėje . Prekių likučio būsena sandėlyje ir internetinėje parduotuvėje išimtinais atvejais gali nesutapti, todėl išlieka galimybė, kad pristatymo terminai gali skirtis nuo nurodytų užsakymo pateikimo metu ir / arba Jūsų užsakymo įvykdyti negalėsime arba įvykdysime tik jo dalį (tokiais atvejais, Pirkėjas yra nedelsiant apie tai informuojamas).

| SND valdiklių techninės charakteristikos | |

| Programinė įranga | ROMANO AIS |

| Cilindrų skaičius [galimos versijos] | 4 [4] |

| Veikia su OBD adapteriu | - |

| OBD sistemos parametrų monitoringas | + |

| Automatinis OBD klaidų atstatymas | + |

| OBD Sistemos Adaptacija - OSA | + |

| Palaiko atvirkštinę OBD korekciją | - |

| Automatinių nustatymų modelis | + |

| Žemėlapio tiesioginė adaptacija - MOSA | - |

| Analoginių įėjimų skaičius, t. lambda jutiklis | 2 |

| Išėjimų skaičius 12 V OUT [išorinių įrenginių valdymas] | |

| RPM rodmenys iš paskirstymo veleno jutiklio | + |

| Galimybė dirbti neprijungus RPM laido | + |

| RPM signalo programinis filtras | + |

| Sumažina šalto variklio dujų įpurškimo trukmę [Cold VAG] | - |

| Benzino pridėjimas ant dujų - benzino purkštukų apsauga | + |

| Palaiko variklius su benzino mikropurškimais | + |

| Benzino persidengimas (benzinas-dujos), pereinant į dujas | + |

| Konfigūruojami 3D korekcijos žemėlapiai pusėms | - |

| Konfigūruojama dujų ir reduktoriaus temp., vak. ir RPM korekcija | - |

| Konfigūruojama dujų slėgio korekcija | - |

| Dujų purkštukų dozavimo koregavimas / pusės konfigūracija | + |

| Master / Slave funkcija | - |

| Dujų purkštukų testavimas | + |

| Reduktoriaus slėgio išleidimas ir nutraukimas (cut-off) | + |

| Dujų purkštukų šildymas | - |

| Pažangi savidiagnostika su užšaldytais kadrais | + |

| Įmontuotas kuro lygio emuliatorius | + |

| Įmontuotas kuro slėgio emuliatorius | + |

| Konfigūruojama variklio temperatūros korekcija naudojant OBD | + |

| SND valdiklių naudojimo charakteristikos | |

| Sky expert sistema [įdiegta] | |

| Hidrofobinė procesoriaus ventiliacija | - |

| Perjungimas esant mažai variklio apkrovai | + |

| 3D žemėlapiai benzino pridėjimui | - |

| Variklio tipas [[MPI - netiesiog. įp., DI - tiesiog. įp.] | [MPI] |

| Palaiko LPG ir CNG | + |

| Valdymo skydelis (jungiklis) | ROMANO AIS |

| Start Stop funkcija | + |

| Dirbtuvių funkcijos [serviso aptarnavimas, slaptažodis ir tt..] | + |

| Darbinių parametrų su registratoriumi peržiūra | + |

| Jei trūksta dujų, aut. grįž prie benz. ir aut. perei. prie dujų | + |

| Avarinio užvedimo dujomis galimybė | + |

| Leistinų avarinių paleidimų skaičiaus nustatymas | - |

| Darbo su dujomis užrakinimas pasibaigus tech. priežiūros laikui | - |

| Garso signalas, rodantis artėjančią tech. priežiūros paslaugą | - |

| Dujų ir benzino veikimo laiko skaitiklis | + |

| Palaikomos transp. priem. po chip-tuning [did. galios varikliai] | + |

| Palaiko STANDARTINIUS/TURBO/VALVETRONIC/HEMI/ECO variklius | + |

| Plati savidiagnostikos sistema | - |

| Slėgio sensorius | Romano Analoginis RPG-E |

| Slėgio sensoriaus spalva | Pilka |